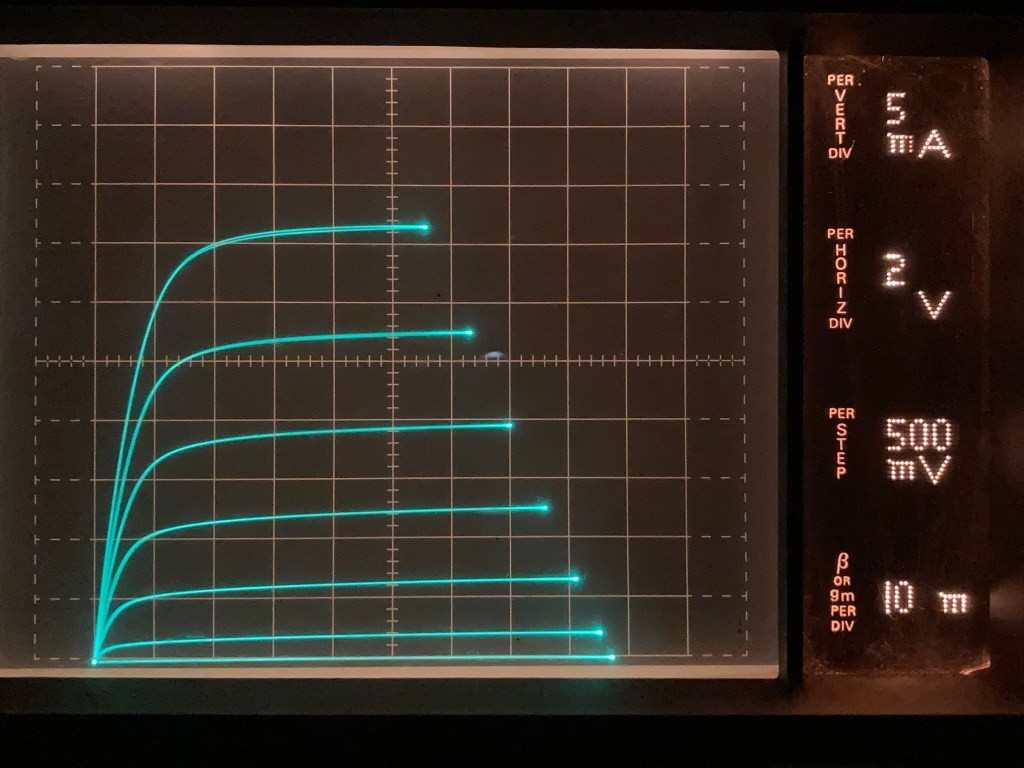

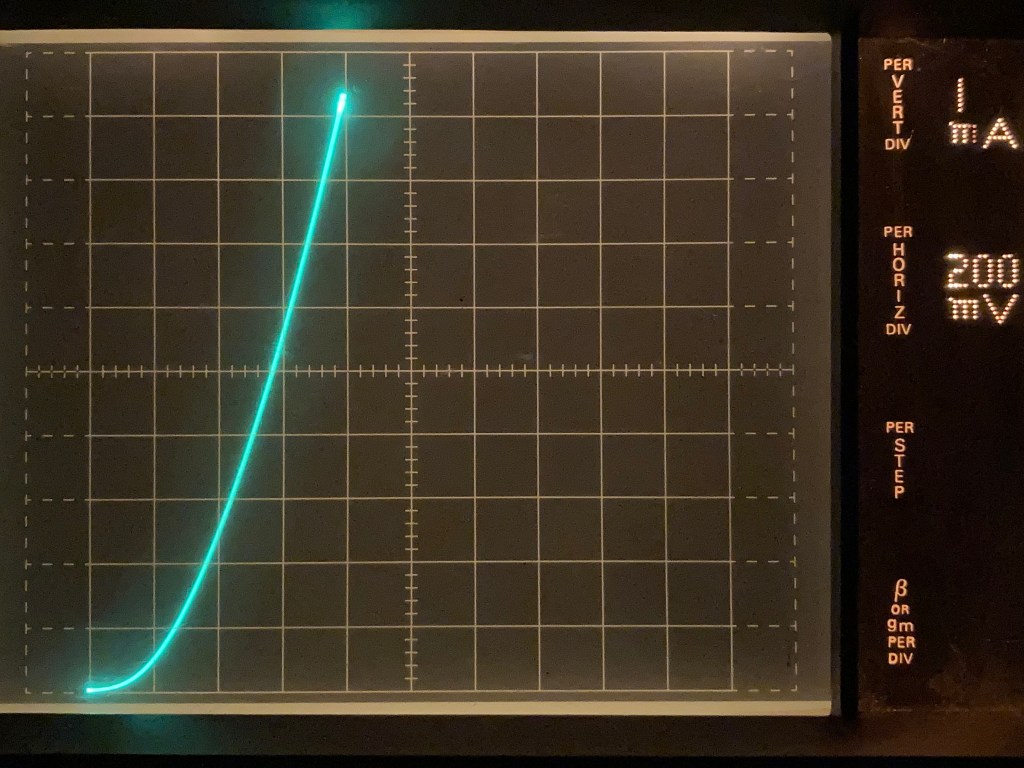

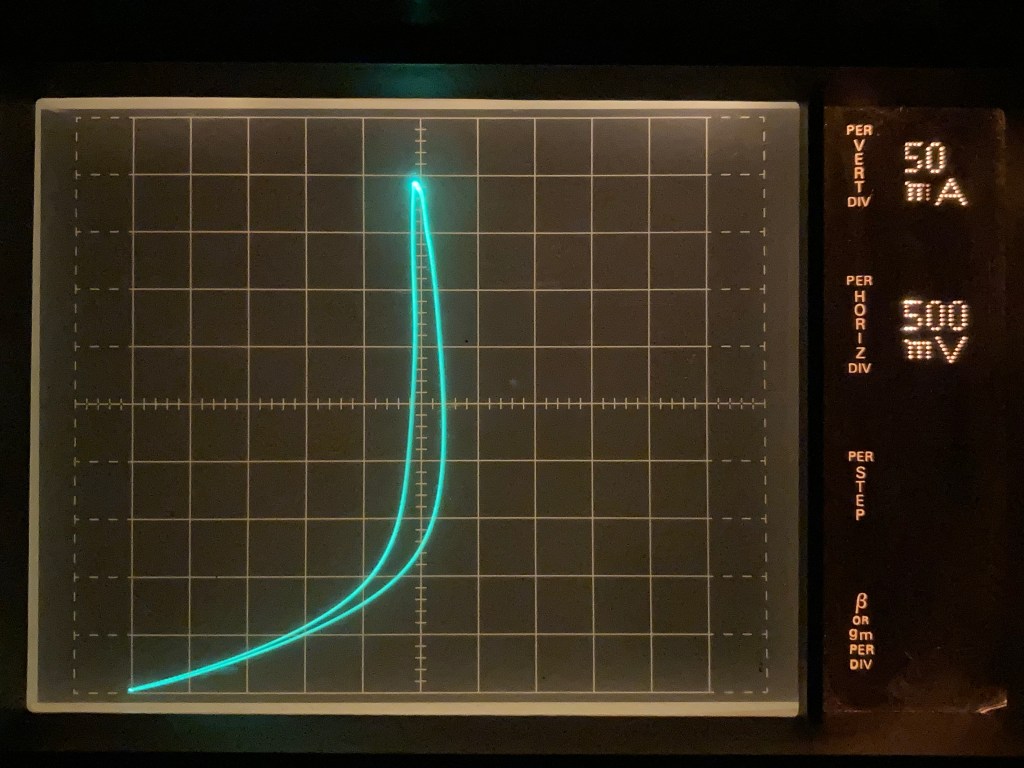

Todays curve is a J310, a depletion mode J-FET.

Todays curve is a J310, a depletion mode J-FET.

Todays post is going to be on those Neon bulbs often used as indicators. I had some 65V small neons to play with.

Did you know that a oscillator could be made with a neon bulb as the only active element? This must be the smallest component count oscillator there is?

Oscillation frequency should be close to 1/(2*pi*R*C). If you build this, please let me know how it works for you. The voltage needs to be approximately twice the neon bulb strike voltage, and R1 should preferably be around 1M ohms. Play around with the values and see what you get.

For the next days I think we will do some active components.

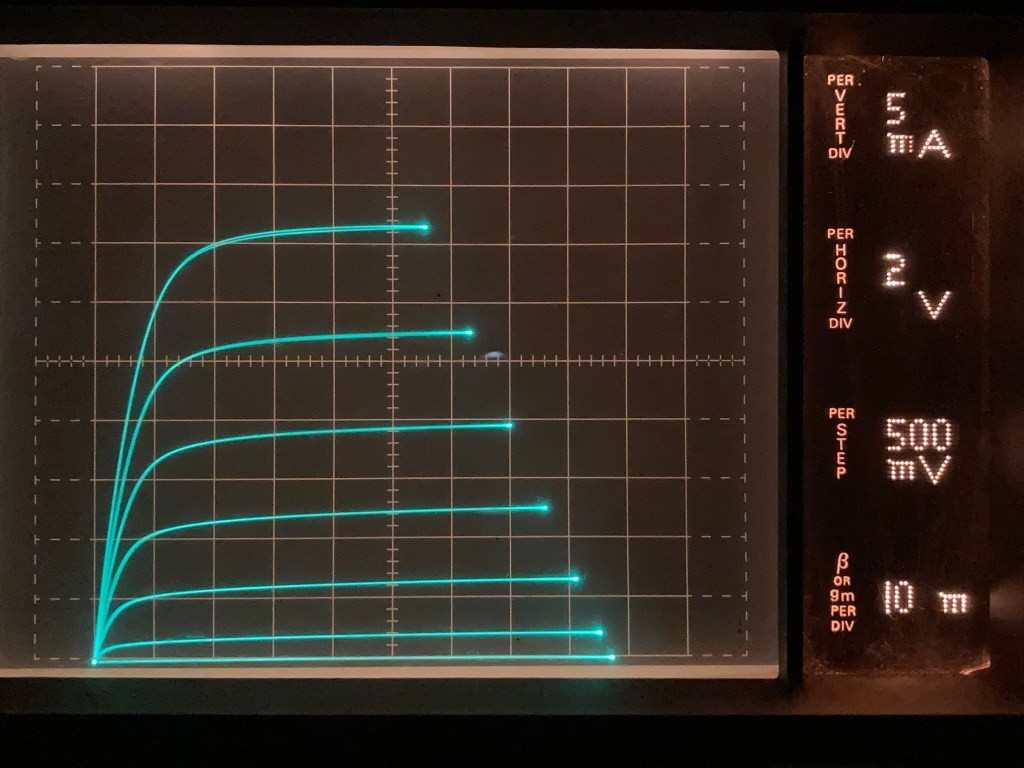

Todays trace is a DIAC or trigger diode.

Notice the retracing of the curve, its a artifact of the curve tracer.

Today it’s time for a couple capacitors.

First out is a leaky 15uF electrolytic:

Then a different capacitor, about 100uF:

The most boring picture, a resistor gives just a slope for the voltage divided by current.

You are welcome to try to figure out the resistance from the slope.

Starting today, the plan is to do a curve trace of one kind of device a day from now untill december 24. Some will just be a single trace, some will have explaination of one kind or another, and some may get full derrivation of the physics.

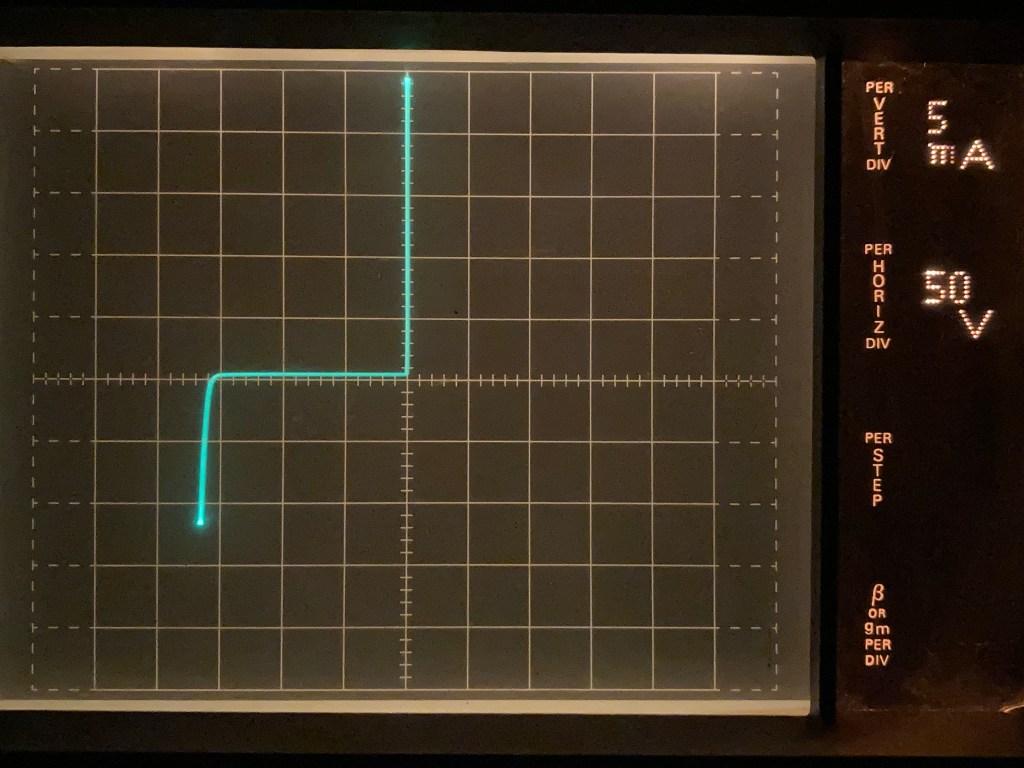

Today we are going to start off with a couple diodes. First out is the trusty 1N4148 diode:

Looking more closely at the forward curve:

From this curve we can determine the slope and use the Shockley diode equation to get the diode parameters.

Doing a standard unnamed Germanium diode then the trace looks like this:

And for fun, here is a Mullard OA81 curve:

I have designed a thermocouple meter for use for obtaining temperature readings from thermocouples. Its used together with the thermal chamber described elsewhere on this site.

The design is done primarily as a programmable instrument, but it has a OLED display, so it can show the current temperature. The programming uses SCPI, the same type of programming strings that most newer (1990 forward) instruments use.

The meter consists of a Empyrean microcontroller from Etherkit and a couple of MAX31855 thermocouple amplifiers. For the MAX31855 it is important to get them from a reputable source, not ebay or aliexpress as there is a lot of fakes around. Display, connectors for the thermocouples and such parts are from ebay.

This design requires a Etherkit Empyrean or other SAMD21 series microcontroller. It will not work with other arduino boards.

The enclosure used is a cheap e-bay case 100x75x35mm. For this I have selected to mill out new font and back panels.

There are 2 PCBs that interlock on this design, a main PCB that fits the enclosure and holds most of the parts and a display PCB for fixing the display in the correct position.

The greenwires are fixed in the last version of the board.

There is a planned extention header (8 pole connector) for a 2. board of thermocouple amplifiers. This way the meter can measure up to 4 points in the same meter.

A couple future points that should be inproved up on is the voltage regulator. This should be replaced with a small switch mode regulator to 5V and a linear regulator down to 3.3V. This have been used in several of my other design and I consider that a building block now. Correctly build it radiates no detectable noise.

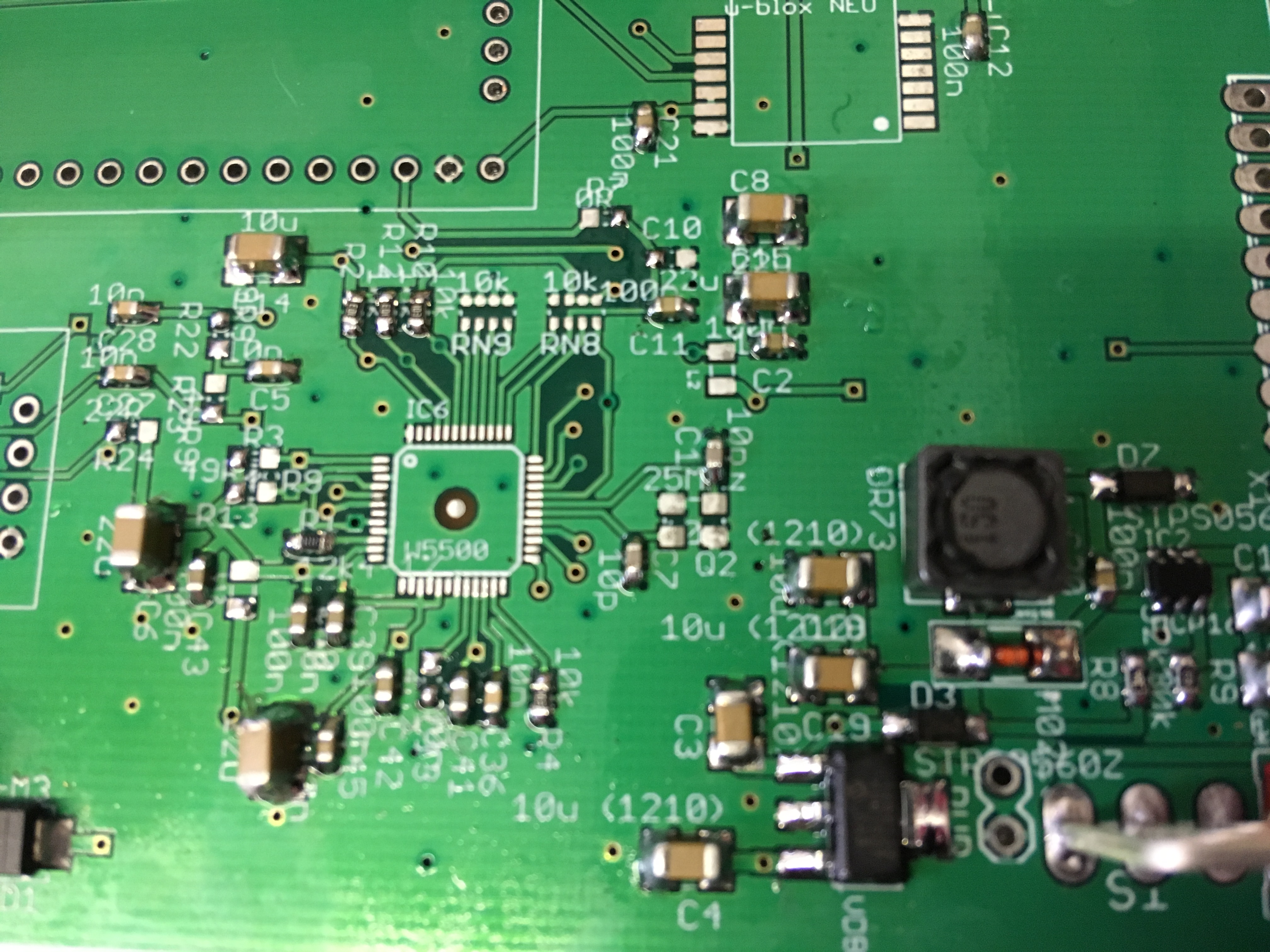

Another point of improvement is that USB is finky at best. It would be better to replace this with a network connection. Experience is that USB times out after a while and that interrupts measurement over longer periods. Adding a network card should be easy and there is plenty of space in the microcontroller.

Feel free to try it, change the code and play around with it. A limited amount of PCB’s and panels may be available from me.

With the closure of Yahoo group, we are seeing a end of an era. Roger KA7EXM just posted this to the EMRFD (Experimental Methods in RF Design) group:

Hello EMRFD Group Members,As you have probably all realized, Yahoo is terminating it’s Group program. It’s been a good thing for all sorts of interest groups including EMRFD. That era has come to an end. We thank Yahoo for their sponsoring efforts to enhance our education and enjoyment.The sales of Experimental Methods in RF Design have slowly decreased and the book is approaching the end of publication. EMRFD Yahoo group activity has slowed to a crawl, often with a month between postings. We have also seen a change in the intensity and depth of the postings. This led us to the conclusion that it is time to close the group. It’s been a useful way for us to share a passion for our common interest in radio frequency electronics.Free time is also becoming a challenge for both of us. One of us (Roger, the Group founder) continues to work in the electronics industry with ever increasing responsibilities and fun. That includes a smattering of RF work. The other (Wes, presently the moderator) is retired, but still busy with some occasional experiments.The simple way to shut things down would be to just let things lapse as Yahoo pulls the plug. We didn’t want to do it this way, for the posting would then be lost. Rather, the files, photos, and messages have been gathered and will be available at www.ka7exm.net/emrfd It will take a while to get all of this data up, but it’s all downloaded. Messages should be live by 27 October, photos and files will post in the coming weeks.After a while, some of you may wish to resurrect the site, perhaps with a new name and new emphasis. All of amateur radio is changing, so it only makes sense for the EMRFD group to evolve.We would both like to thank all of you for sharing your thoughts and experimental results and designs. The posts have been enlightening and stimulating. Special thanks go to coauthors Rick Campbell, KK7B, and Bob Larkin, W7PUA.73Roger, KA7EXM, and Wes, W7ZOI.

This post is in Norwegian. It should be possible to get most of the gist from it if you don’t speak norwegian, or you could try one of the many other explaination of the setup available on the web.

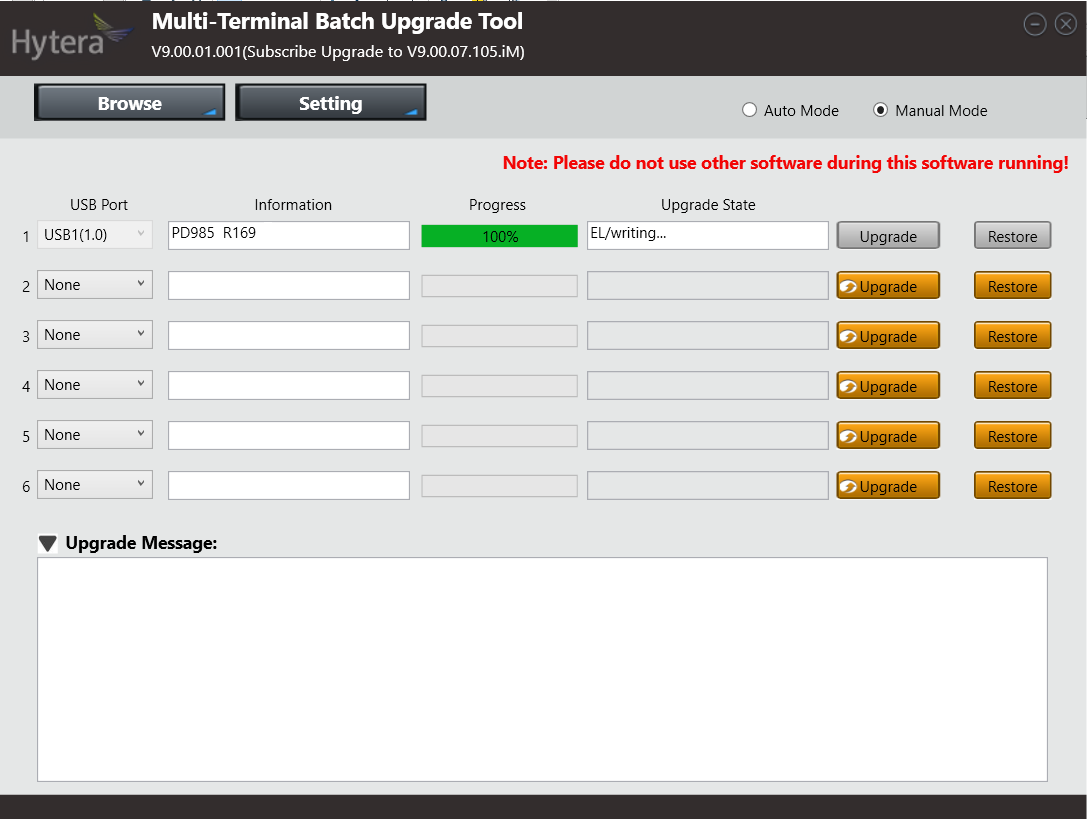

For denne forklaringen brukes en Hytera PD985 med GPS. Alt som er forklart her gjelder for PD6, PD7 og PD9, samt det meste for de noe enklere PD4 og PD5 radioene til Hytera. For mobilstasjoner mangler det ett par små steg. Observer at PD4 og PD5 serie har egen utgave av programeringssoftware, samt andre nummer for firmware. Man kan annta at nye radioer fra forhandler leveres med en av de siste utgavene av firmware. For samtlige radioer er det helt nødvendig å ha tilgang på programeringskabel, selv om de fleste innstillingene kan settes via tastaturet. For å se bildene bedre, kan du høyreklikke på de, og velge “åpne bildet i ny fane”.

Last ned og innstaller siste utgave av Customer Programming Software (CPS) samt Subscriber Batch Upgrade (SBU) fra: https://www.hamdigitaal.nl/hytera-software-1/ og https://www.hamdigitaal.nl/hytera-firmware/

Dersom du ikke har en digital ID fra før, får du en her: https://register.ham-digital.org/

For å oppdatere firmwaren i radioen, kjør SBU. Dette er ett program som stiller store krav til tilgjengelig minne i radioen, slik at det er en fordel å re-starte PC’en før du starter det programmet. Koble radioen til PC, eventuell bryter på kabelen settes til DL, og sørg for at radioen er på før du starter programmet. Dersom radioen ikke går i oppdateringsmode automatisk, skru av radioen, hold inne orange «nødknapp» og PTT når du skrur på radioen. Oppdatering av firmware bør gjøres hver gang CPS oppdateres, ellers vil det være umulig å tilbakestille radioen til fabrikkinnstillinger. Dersom din radio har lavere firmware version enn V7.00 må det oppgraderes til V7 før det oppgraderes til siste versjon.

Steng SBU før CPS startes. Dersom det forsøkes å skrive til radioen med begge programmer aktive på PC, vil skrivingen feile. Sett bryteren på programeringskabelen tilbake til CPS før du forsøker å skrive til radioen.

Når CPS er startet trykk «Read». Da lastes oppsettet i radioen inn i programmet. Utvid Common og Conventional. XPT Trunking er for større linkede systemer med flere repeatere koblet sammen på samme sted. Dette brukes ikke til amatørradio.

Under Common – Settings:

Sett «Radio Alias» til ditt kallesignal + navn. I mitt tilfelle LA3PNA Thomas. Sett «Power-on Message Type» til «Radio Alias». Dersom du ønsker at det skal settes passord for å bruke, lese eller skrive til radioen, settes det her. Du kan velge norsk språk under «Language», vær obs på at enkelte oversettelser har noen feil.

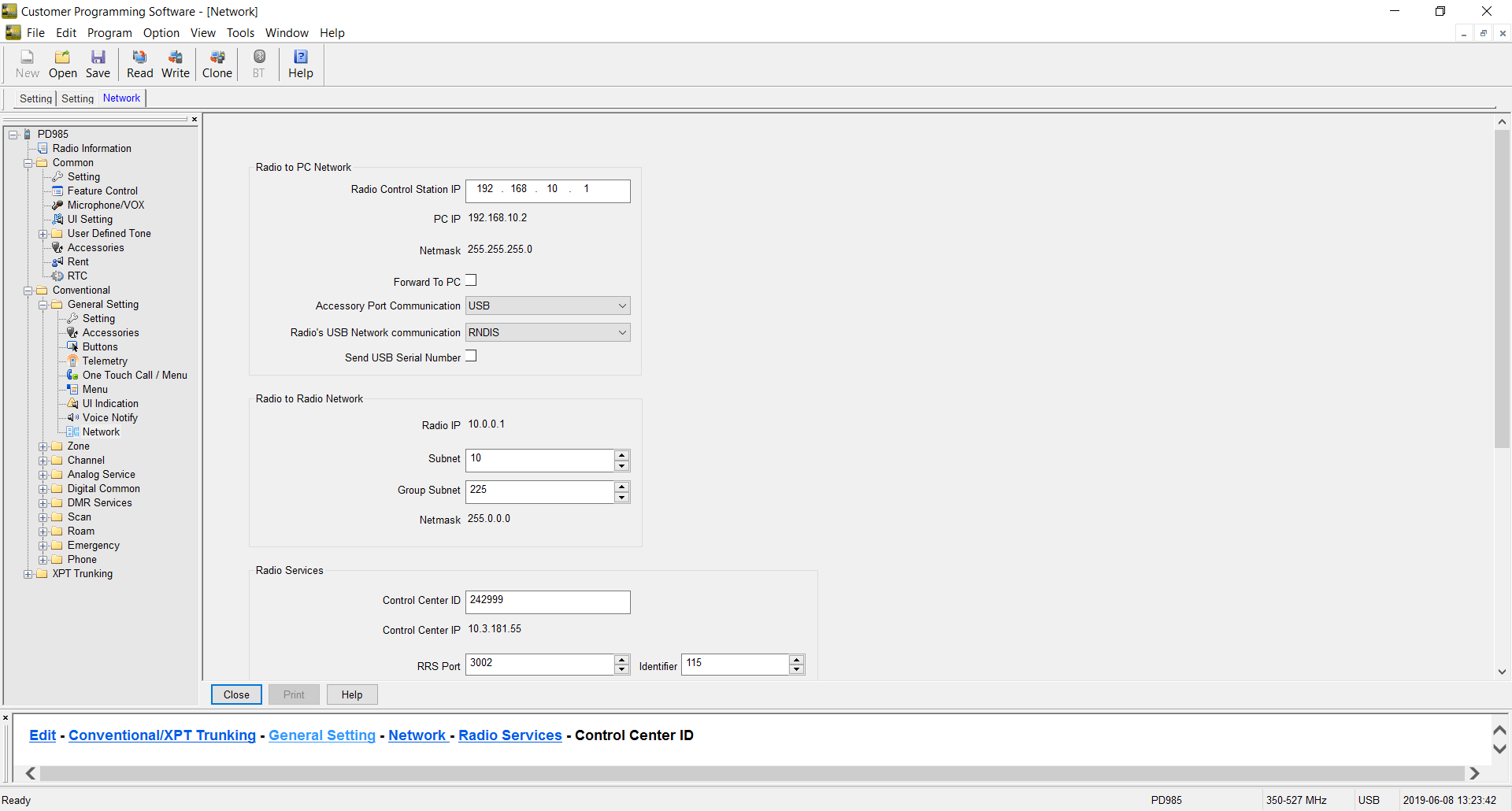

Under Conventional – General settings – Network:

Scroll ned til «Control Center ID» denne settes for Brandmeister i Norge til 242999. La alle andre innstillinger stå som de er.

Under Conventional – Digital Common – Basic:

«Radio ID» settes til din digitale ID. Denne fikk du tilsendt på e-post når du registrerte deg som digital bruker.

Lengere ned, under «miscellaneous» settes «Data Bearer Service» til «Compressed IP»

Huk og ut «Auto Add Contacts» dersom du ønsker at de du hører på luften, automatisk skal legges til som kontakter i kontaktlisten.

Det neste er å definere «kontakter». Dette er både de talegruppene vi ønsker å bruke, og personer vi sakker med. For enkelhets skyld vil jeg kun definere den nasjonale talegruppen 242, men det finnes mange andre som brukes. Lokalt bruker vi ID til en repeater (242650) slik at vi alltid kommer ut på den lokale repeateren, selv om vi skulle være på ett annet sted. Det er en fordel å se i Brandmeister for de lokale repeaterene du definerer. Både ID og at du velger rett tidsluke finner du i Brandmeister. Dersom du ikke har rett tidsluke, vil repeateren dynamisk linke til det tidsluke du bruker. Resultatet av dette er at du legger beslag på begge tidsluker, og hindrer en annen QSO som kunne gått samtidig.

Under Conventional – DMR Services – Contact:

Legg til «Nasjonal 242» som «Group call» og med Call ID «242»

Ut over dette trenger vi ikke å definere noen flere kontakter nå, vi kan definere de når vi legger til flere kanaler.

Under Conventional – Channel – Digital Channel:

Velg «CH D1», og rediger denne slik at den passer med din lokale DMR repeater. Jeg har valgt å kalle min kanal LD3DV 242, siden dette er LD3DV, i talegruppe 242.

Start med å sette korrekt frekvens. Dette er nødvendig for å få huket ut «Multisite IP Connect».

Sett RX group list til «None», TX contact name til «Nasjonal 242», «Location Info Revert Channel» og «RSS Revert Channel» settes til «Selected». «Emergency system» og «Phone system» settes til «None». «Power level» settes til det som måtte passe. «TX admit» settes til «Channel Free». «TX time out time» settes til ett passende nivå. 60 sekunder er ofte litt lite for amatørtrafikk.

Under Conventional – Zone – Zone1:

Zone er en utvidelse av kanallisten hvor man kan ha en zone for repeatere, en for simplex osv.

I dette tilfellet velger vi bare å fjerne alle kanalene vi ikke har redigert, så «LD3DV 242 står tilbake alene.

[9]

Dersom du nå laster opp denne konfigurasjonen til radioen, skal du kunne prøve den mot den nasjonale talegruppen.

Samme prosedyre med innlegging av kontakt, kanal, og så i zone brukes for alle andre kanaler du ønsker å ha i radioen. Analoge kanaler kan fint blandes med digitale i samme zone.

For radioer med innebygget GPS:

For å få en knapp som sender GPS posisjon, velg Conventional – General Settings – Button, og sett «SK2 long» til «GPS Report».

Velg videre Conventional – General settings – Accessories og under «GPS trigger» huk av «Button». Her har du og muligheten til å sette at den automatisk sender posisjonsrapport etter en gitt tid eller avstand. Under «voice w/Location» huk av både «Voice w/Location» og «PTT». Da sendes posisjonen automatisk når du trykker inn PTT.

Tillegg 05/02-24: Dersom ikke DPRS (APRS) fungerer, skru av GPS data compression under General-> Settings -> Accesories

Several people I know have been asking me for advice when it comes to getting boards assembled lately, so I wanted to write-up my experiences and some tips.

At the design process, I get that you just want to churn out your boards, but now is the time to decide on your assembler. Several of the Asian PCB manufacturers have a turn-key solution where you can send them your board files and a BOM, pay them and you get back the boards ready assembled. For simpler things that may be a reasonable approach, but be aware that you have no control on the supply chain this way. Those 1% resistors making up a reference voltage may now be 5% or worse. That microcontroller or low noise Op-Amp may now be a fake. I like to use a local assembler within driving distance, and to be there when they do a run. That way, I can catch problems during assembly without doing a whole run, if we need to rework a panel. Often you can pick up great hints from the production personnel when assembling your boards.

Questions to ask your assembler when doing the first contact:

When choosing an assembler, make sure you know how many boards you need to assemble (and sell) in order for it to break even. I know someone doing runs of 100 boards at a time, when the break even point was 122 boards. No wonder they didn’t make money on that run.

Observe that in high cost countries, finding a assembler willing to do a couple hundred boards can be difficult. If they complain about stopping their high volume work to do your few boards, find a different assembler. Experience says that the prices will be high, and the bickering constant.

Also make sure you have a plan for testing and assembling the boards into their final enclosure. Testing can be quite complicated! Time spent during the design process avoids time being spent reworking or scrapping boards.

At this point, you should try hard to reduce the number of lines in your BOM. Can that 20K resistor you need 1 off, be made up of 2 10K in series? Are you sure you need both 22µF and 10µF capacitors? or could just 22µF do? If you pay per feeder (you probably do), reducing the number of feeders needed helps to reduce the setup cost and lower your break even point.

All your parts have arrived, and you are ready to get the board assembled. At your assembler, you are not the only customer so make sure to not film nor photograph anything other than your board. Ask first.

Note added 25/12-19: Several of the board MFGs use some kind of pad fitting when creating the solder paste stencils. This may majorly mess up carefully tuned paste layers, in addition to the problems it makes if you use say a Stencil8. It may be worth it to point out that the stencil should be from the paste layer.