Some time back (2016 timeframe) I built a test chamber out of an inexpensive freezer, after having several project that required taking some thermal data over the expected useable range. I was looking for a used laboratory freezer that goes down to -60° or lower, but none seems available used.

The freezer uses “pentane C” cooling media, and the initial test suggested that before modification, the freezer, with the pump running all the time would go down to -26°C.

After confirming that the freezer would work, it was time to void the warranty. What better way, than by drilling a hole through the side of the freezer?

I choose to drill through the plastic with a small pilot drill, then poke around to see if there was any cooling tubes in the side. That way I hopefully I would be able to avoid cutting any of the tubes. Given that I couldn’t feel anything in the foam insulation, it was time for the hole saw. With a hole through the side of the bottom compartment, a 36mm plastic tube was fitted, some foam spray was used to fix the defects and some clear silicone sealed the gap between the tube and the side of the freezer.

The idea I started with was to make a proper, insulated patch panel, with both coax and DC connectors, but after some thinking, the tube filled with a rag seemed like a more flexible approach.

Ripping out the thermostat and sensor tube was quite easy, threading the sensor cable for a ready-made 1-wire sensor (got this via bobcatinabox.com some time back). Drilling a hole in the wall of the small compartment was done by poking through the insulation from the back with a pice of wire, then when confirming it was clear off the cooling tubes and drilling through.

A 12V PTC heater with fan was modified so that the fan can run all the time, and fitted to the shelf. This way there will be constant air circulation inside, and the heater can be controlled by the microcontroller.

On the back of the freezer, the connector block for the freezer had an unused terminal that was repurposed as a terminal for the live wire that before had gone to the thermostat. A 12V 20A switch mode power supply was added, and fixed to the back wall with a couple M3 screws and nuts.

A Arduino was fixed above the power supply, and a small pice of wearoboard with some relays and driver transistors to switch the power to the pump motor and to the heater.

The program running on the microcontroller is a fuzzy logic implementation with a 2°C hysteris. There is also some timing logic to not turn on the pump before the back pressure has bled trough, or the fuse will blow. I started out with some SCR’s but the cheap eBay SCR I bought had too much loss before it caught fire.

The program can be found here: https://github.com/la3pna/thermal-chamber

I intend to implement a proper dual PID for the controller one day, as keeping temperatures within 0.5°C should not be too difficult. Adding network interface in addition to the USB and a propper way of handling those messages would make it more versatile.

There is currently no cap on how hot it can become inside, but I suspect the plastic casing will not take well to having it run at high temperature for long time.

The inside usable size is approx 320x320x180mm, so there is no way of fitting a 19″ rack in there, but for smaller parts, it will do OK. Now I just need to build the multiple termocouple amplifiers into a box with some method of reading it out.

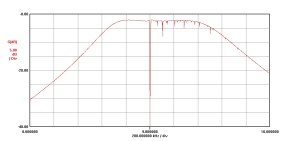

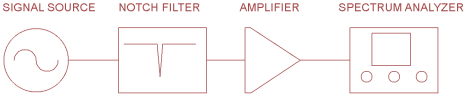

An example of measured data: